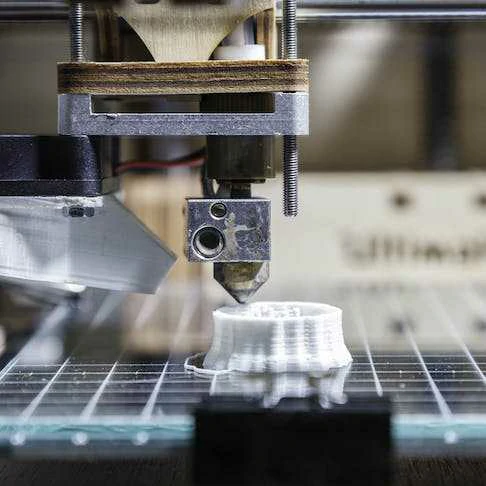

In additive manufacturing, accurate cost estimation and budget planning are vital for project success. 3D printing cost calculators are crucial in providing accurate cost estimations, enabling manufacturers to plan budgets effectively and make informed decisions based on financial considerations. Manufacturers can optimize costs, minimize financial risks, and achieve their desired outcomes in additive manufacturing projects using these calculators.

Additional 3D printing processes such as stereolithography, selective laser sintering, fused deposition modeling, HP multi jet fusion 3D printing, carbon digital light synthesis 3D printing, and direct metal laser sintering, come with unique characteristics, materials, and cost considerations. A comprehensive 3D printing cost calculator takes into account the specific requirements and parameters associated with these processes to provide accurate cost estimations for a wide range of 3D printing projects.

Factors Affecting 3D Printing Costs

Several factors influence the overall expenses of 3D printing projects. Understanding these factors is essential for accurate cost calculations and efficient budget allocation. The key factors include material selection, part complexity, build volume, printing speed, and post-processing requirements. Manufacturers must consider these factors and implement strategies to optimize costs at each stage of the 3D printing process.

Material Selection

The choice of the printing material significantly impacts 3D printing costs. Different materials, such as filaments, resins, and metals, vary in cost and availability, leading to variations in overall material cost. Manufacturers must carefully consider material properties, cost-efficiency, and project requirements to select the most suitable material that aligns with their budgetary goals.

Part Complexity

The complexity of a 3D printed part affects the overall printing costs. Intricate designs, overhangs, and the need for support structures increase print time and post-processing requirements, subsequently impacting expenses. By optimizing part designs and minimizing unnecessary complexity, manufacturers can reduce costs without compromising the desired quality of the end product.

Build Volume

The build volume of a 3D printer plays a significant role in cost calculations. Larger print sizes may require longer printing time and consume more material, leading to higher costs per unit volume. Manufacturers can achieve cost savings while maintaining production efficiency by considering the appropriate build volume for a given project and optimizing print sizes.

Printing Speed

Printing speed directly affects 3D printing costs. Layer height, print speed, and production efficiency impact the overall cost per unit of time. Faster printing speeds may increase energy consumption and machine utilization, but they can also enhance production efficiency, reducing the cost per unit of time. Manufacturers must balance speed, quality, and cost-effectiveness for optimal results.

Post-Processing

Post-processing requirements significantly contribute to 3D printing costs. Activities like support removal, sanding, painting, and finishing add to the overall expenses, including labor costs, such as hourly rate, and time investment. Manufacturers must carefully evaluate post-processing needs and explore cost-effective techniques to achieve printed parts' desired aesthetics and functionality while minimizing additional expenses.

How 3D Printing Cost Calculators Work

3D printing cost calculators employ advanced algorithms and formulas to estimate printing costs accurately. These calculators take inputs such as material type, part complexity, build volume, printing speed, and post-processing requirements to calculate the overall expenses. By utilizing these calculators, manufacturers gain access to reliable cost estimations, enabling them to make informed decisions, optimize budgets, and ensure cost-effective additive manufacturing processes.

Benefits of Using a 3D Printing Cost Calculator

Utilizing a 3D printing cost calculator offers numerous benefits for manufacturers engaged in additive manufacturing. These calculators facilitate cost optimization, allowing manufacturers to control their budgets effectively and avoid unexpected financial hurdles. Manufacturers can plan projects efficiently, allocate resources appropriately, improve material efficiency, and achieve improved productivity and profitability in their 3D printing operations using cost calculators.

Summary

This article presented 3D printing cost calculators, explained them, and discussed their importance and factors affecting cost. To learn more about 3D printing, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry's network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

.webp)