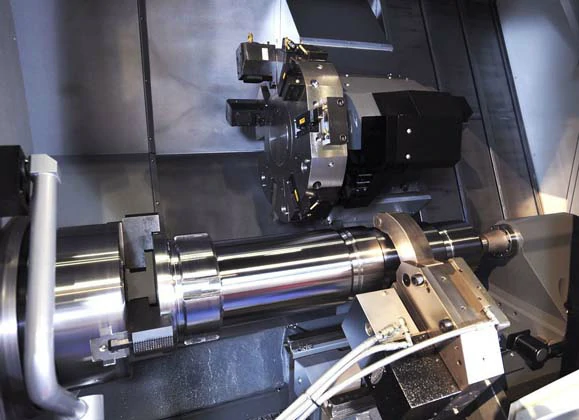

Five-axis CNC programming technology is revolutionizing the field of parts processing. With its ability to manipulate a workpiece along five different axes simultaneously, this technology offers numerous advantages over traditional methods. In this article, we will explore the benefits of five-axis CNC programming technology in parts processing.

Improved Precision

One of the major advantages of five-axis CNC programming technology is its ability to achieve higher precision in parts processing. Traditional machining methods often require multiple setups and repositioning of the workpiece to access different angles. This can introduce cumulative errors and reduce the overall accuracy of the finished part. However, with five-axis CNC programming, the workpiece can be rotated and tilted in any direction, allowing for precise machining from multiple angles without the need for repositioning. This results in superior accuracy and a higher quality finished product.

Increased Efficiency

Five-axis CNC programming technology also offers increased efficiency in parts processing. By utilizing multiple machining operations simultaneously, the time required to complete complex parts is significantly reduced. Traditional methods may require multiple setups and tool changes to access all necessary angles, resulting in time-consuming processes. In contrast, five-axis CNC programming allows for simultaneous machining of multiple features, drastically reducing the overall production time. This increased efficiency not only saves time but also reduces costs and improves productivity.

Expanded Capabilities

The versatility of five-axis CNC programming technology allows for the production of complex parts that were previously impossible or difficult to manufacture. With the ability to rotate and tilt the workpiece in any direction, intricate geometries and intricate features can be machined with ease. This opens up new possibilities for designers and engineers, allowing them to create innovative and intricate parts that were once unimaginable. The expanded capabilities of five-axis CNC programming technology enable manufacturers to produce highly customized and unique parts that meet the specific requirements of their customers.

Reduced Setup Time

Another advantage of five-axis CNC programming technology is the reduction in setup time. Traditional machining methods often require extensive setup, including the alignment of workpieces and the installation of fixtures. This can be a time-consuming process and can prolong lead times. However, with five-axis CNC programming, the need for alignment and multiple setups is minimized. The ability to manipulate the workpiece along multiple axes eliminates the need for complex fixtures and alignment procedures. As a result, setup time is significantly reduced, allowing for faster production and shorter lead times.

Conclusion

In conclusion, five-axis CNC programming technology offers numerous advantages in parts processing. From improved precision and increased efficiency to expanded capabilities and reduced setup time, this technology is revolutionizing the manufacturing industry. By embracing this innovative technology, manufacturers can achieve higher quality parts, reduce costs, and improve overall productivity. As the demand for complex and intricate parts continues to grow, the adoption of five-axis CNC programming technology will become increasingly important in staying competitive in the industry.

.webp)