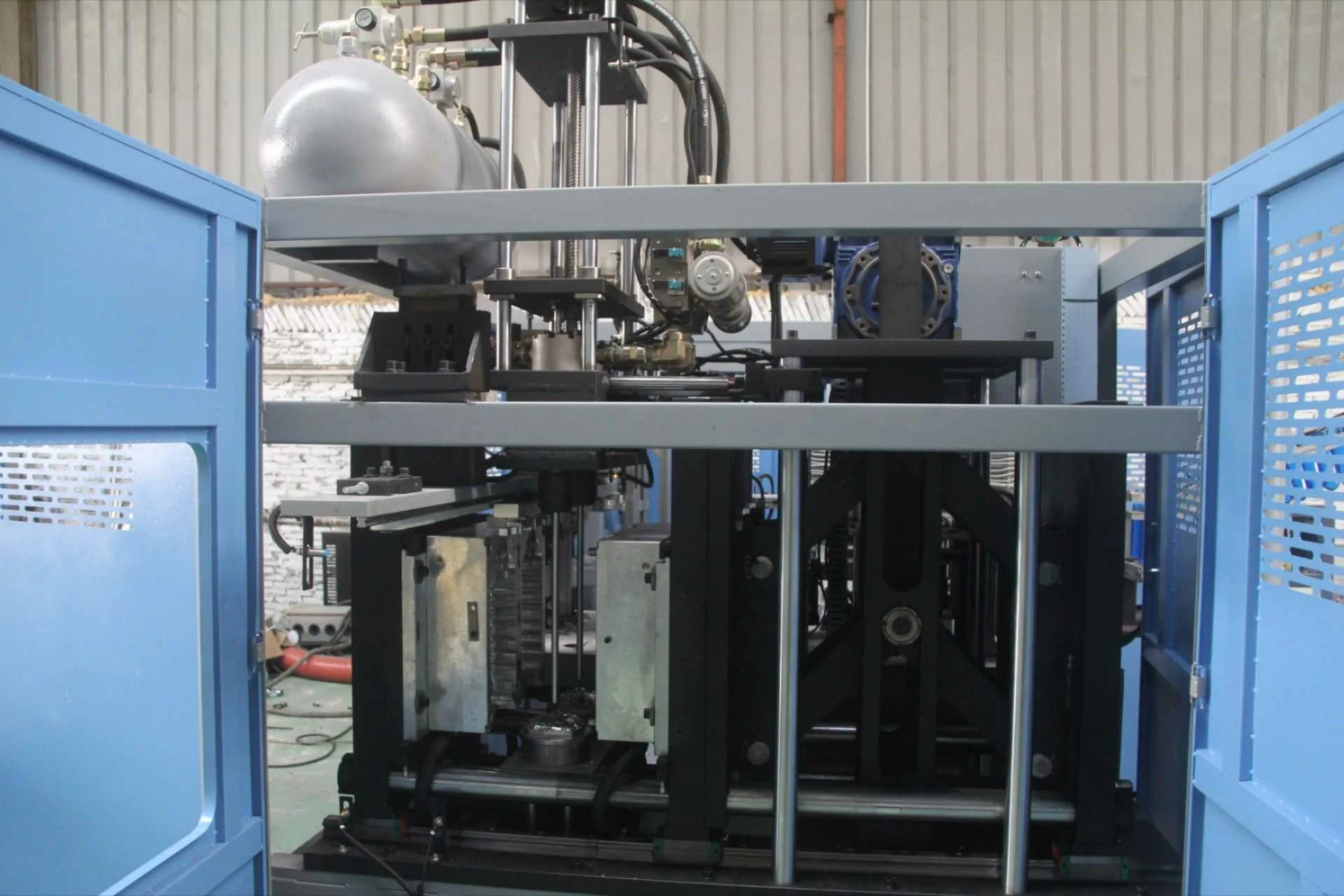

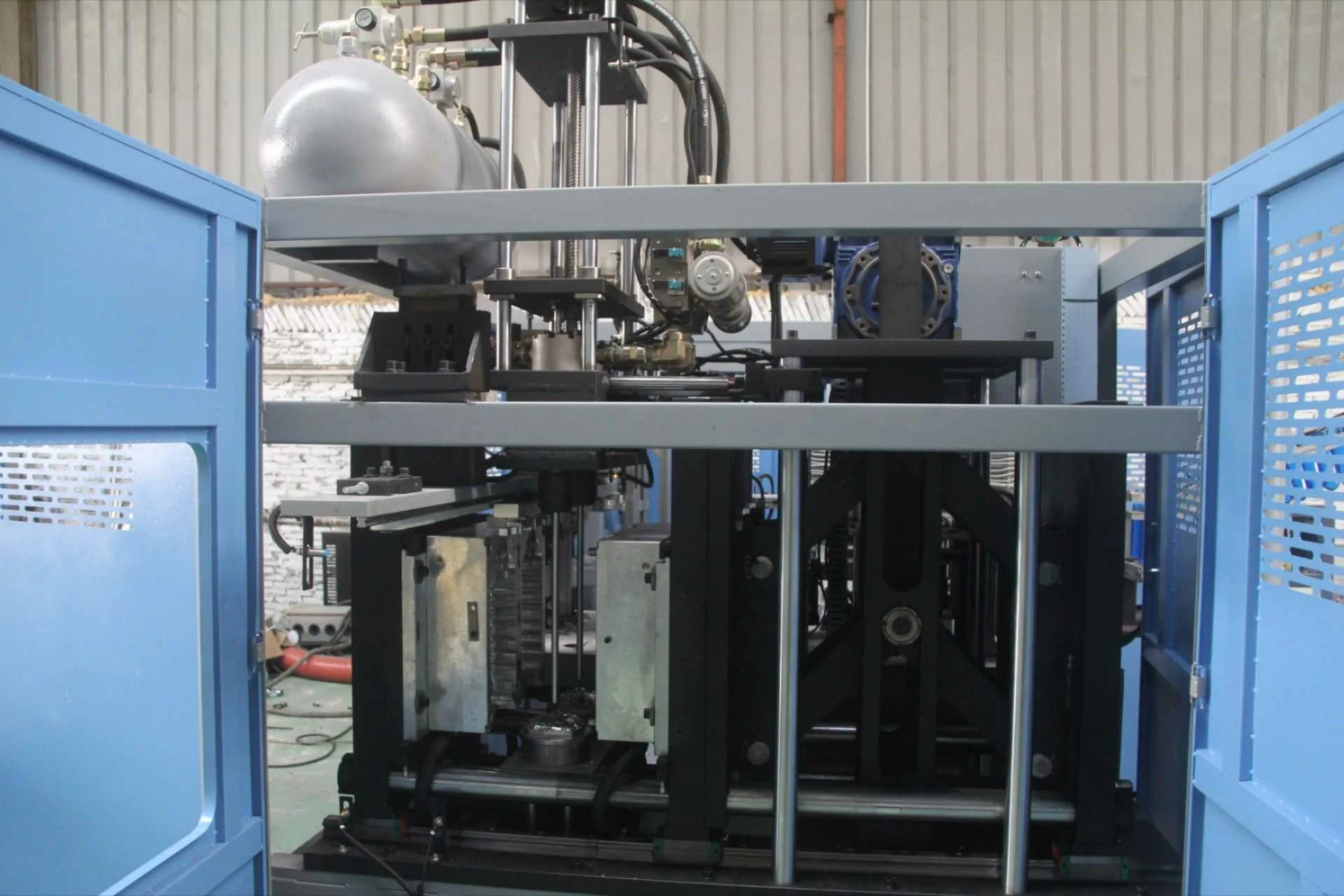

Blow molding is a popular manufacturing process used to produce hollow plastic parts. It offers several advantages over other methods, including cost-effectiveness, design flexibility, and the ability to produce complex shapes. Navigating blow molding production can be challenging, especially for those new to the industry. In this article, we will explore the key aspects of blow molding production and provide insights to help you navigate the process effectively.

Understanding Blow Molding Production

Blow molding production involves the use of a mold to shape molten plastic into a desired form. The process consists of several steps, including the melting and extrusion of plastic, the formation of a parison (a hollow tube of plastic), and the blowing of the parison into the mold cavity. Once the plastic cools and solidifies, the mold opens, and the finished product is ejected.

Types of Blow Molding

There are three main types of blow molding: extrusion blow molding, injection blow molding, and stretch blow molding. Each type has its unique advantages and applications.

1. Extrusion Blow Molding

Extrusion blow molding is the most common type of blow molding used for large-scale production. It involves the extrusion of a continuous tube of molten plastic, which is then clamped into a mold and blown to the desired shape. This process is suitable for producing large and medium-sized hollow parts such as bottles, containers, and automotive components.

2. Injection Blow Molding

Injection blow molding combines the principles of injection molding and blow molding. It starts with the injection of molten plastic into a mold cavity to create a preform. The preform is then transferred to a blow mold, where it is inflated to the final shape. Injection blow molding is ideal for producing small and intricate parts, such as medical devices and single-serve beverage containers.

3. Stretch Blow Molding

Stretch blow molding is commonly used to produce PET (polyethylene terephthalate) bottles for beverages and personal care products. It involves the injection of a preform into a mold, followed by stretching and blowing to achieve the desired shape. Stretch blow molding offers excellent clarity, durability, and resistance to gas permeation.

Key Considerations in Blow Molding Production

1. Material Selection

Choosing the right material is crucial in blow molding production. Common materials include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and PET. Factors to consider when selecting a material include its mechanical properties, chemical resistance, and suitability for the intended application.

2. Mold Design

The design of the mold will impact the quality and functionality of the final product. Key considerations include the part geometry, wall thickness distribution, draft angles, and the presence of undercuts. Collaborating with an experienced mold designer or blow molding manufacturer is essential to ensure optimal mold design.

3. Process Optimization

Optimizing the blow molding process can help improve productivity, reduce cycle times, and enhance the quality of the finished product. Variables to consider include temperature, pressure, cooling time, and parison thickness. Conducting thorough testing and analysis can help identify areas for process improvement.

4. Quality Control

Implementing effective quality control measures is essential to ensure consistent production of high-quality parts. This includes regular inspection of molds, monitoring of process parameters, and conducting tests on finished products. Any deviations should be promptly addressed to prevent defects and ensure customer satisfaction.

Navigating Blow Molding Challenges

While blow molding offers numerous benefits, it also presents some challenges that need to be navigated effectively. These challenges include:

1. Uniform Wall Thickness

Achieving uniform wall thickness throughout the part can be challenging, especially for complex geometries. Uneven wall thickness can lead to structural weaknesses and aesthetic issues. Careful mold design and process optimization are crucial to address this challenge.

2. Flashing

Flash refers to excess plastic that escapes from the mold during the blowing process, resulting in a thin, unwanted edge on the finished part. Flashing can compromise the functionality and appearance of the product. Proper mold maintenance and adjustment can help minimize flashing.

3. Material Selection for Recycling

Blow molding production generates plastic waste that needs to be managed responsibly. Selecting materials that are easily recyclable, such as high-density polyethylene (HDPE) or PET, can help reduce environmental impact. Collaborating with recycling facilities and following sustainable practices is essential for responsible waste management.

Navigating blow molding production requires a deep understanding of the process, careful consideration of key factors, and effective problem-solving skills. By selecting the right materials, optimizing the process, and implementing quality control measures, manufacturers can achieve consistent production of high-quality blow molded parts. With continuous improvement and a focus on sustainability, blow molding remains a reliable and versatile manufacturing method in various industries.

https://abcicon.com/